| Steam Jet Mill | ||||||||||||||||||||||||||||||||||||||||||

+ Fluidized Bed Classifying Jet Mill + Precision Air Classifier + Classifying Impact Mill + Abrasive Powder Classifying Jet Mill/ Shaping + Bag Collector + Ultrafine Powder Processing Line

|

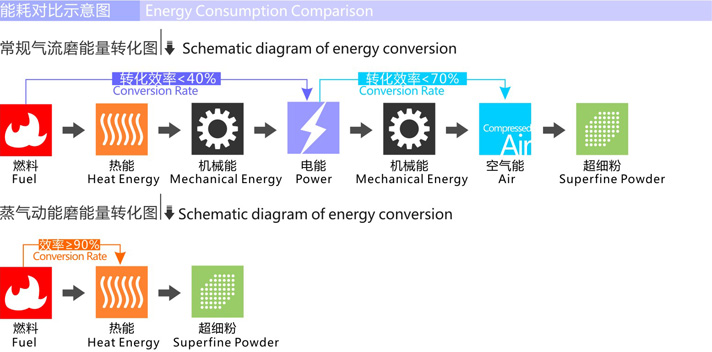

Working Principle: Steam jet mill adopts high temperature mechanical technology and uses hot steam as media for high speed movement to perform materials pulverization. The finest particles are brought to collector by turbine grader, the coarser grains will be swirled back to grinding chamber. the whole production line is dry-type processing due to the steam in the system keeps overheating. LNGS Steam Jet Mill is a new superfine pulverizing device, is our patent product. Main features: high efficiency grinding, large capacity, lower energy consumption, unit power consumption is only 1/5~1/8 of jet mill. 1.High efficiency grading. The flow speed of steam jet mill is up to 1000m/s(convectional air jet mill is 500m/s). 2.Lower energy consumption. Steam jet mill uses superheated steam as kinetic energy, the rate of energy usage is up to 90%. |

|||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

| 3.Large capacity. The dimension of jet mill depends on the size of steam source device, the biggest air compressor is 200~300m3/min currently, its hard to large scale, however the industrial boiler is more popularization, it’s easy to meet the requirements of large steam jet mill, greatly improving the single equipment capacity. 4.Grinding in closed system, to avoid contact with air. It has protect blast, antistatic, anti-oxidation. 5.The product has well dispersion, and simultaneous dry function in processing. 6.Due to reduce the processing cost, greatly expand the scope of processing, this equipment can be used for high added value non-heating sensitive material and non-metallic mineral material superfine pulverizing. |

||||||||||||||||||||||||||||||||||||||||||

| ■Application field | ||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

| ■Main technical parameter | ||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||